Manufacturing

Manufacturers have streamlined their operations using traditional methods so long. They can leverage their own data to further boost productivity and profitability. Data can be put to work by harnessing information from various sources – equipment controls, PLC, industrial internet of things (IIOT),input, output, process parameters etc. through predictive and machine learning algorithms for improving operations and making it more intelligent.

In a venture driving operations excellence through data analytics, Business Brio was entrusted with a project by one of the biggest producers of pig iron and ductile iron pipes. The company produces more than 700K tons of pig iron annually and was on the look out to find a solution that can optimize their bottom line of operations. Business Brio had to study the processes - understand the existing manual and electronic data collection, do diligence on data quality using gage R&R, and then build, validate and refine models using advanced methods of supervised machine learning like DOE and RSM. The client was further enabled with statistical controls for preventive as well as predictive models for uninterrupted operations starting from sinter plant, metal blast furnace to the centrifugal casting.

We partner with you

for transitioning to Industry 4.0

Forecasting

At Business Brio, we have used Single Exponential Smooth, Double Exponential Smooth, ARIMA and back-propagation neural network. We did find Neural network to have better forecasting performance than the classical forecasting algorithms in case of wind energy forecasting for a particular project and won the NASSCOM Analytics Innovation award in 2015 for effectively using the same for business.

Optimization

Methods like Goal Node, Integer Linear Program, Simplex Method and Interior Point Method are used depending on the context and relevance. At Business Brio we use Lindo as a tool for optimization.

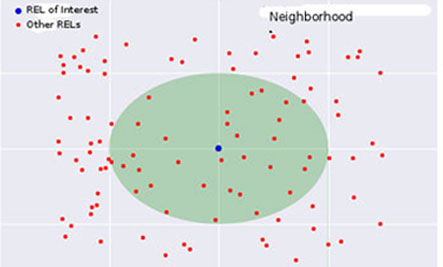

Machine Learning

Unsupervised and supervised learning methods like regression, support vector machines (SVM),KNN, K-means, PCA are used to recognize patterns and make data-driven predictions or decision outputs. We extensively use Python and R for applying the algorithms.

Decision Trees

CART, CHAID, Random Forests, mathematical and computational techniques are used to aid the categorization and classification of a given data information. Apart from programming tools, we also use WEKA for decision trees.

Sentiment Analysis

Opinion mining or emotion AI refers to the use of natural language processing, text analysis, and computational linguistics to systematically identify, extract, quantify, and study affective states and subjective information. In past projects, we have heavily used LSE, HSA, text mining for semantic algorithms.

Predictive Maintenance

Applications

Supply Chain Management

Ongoing Operations Excellence

H&S/Environment Compliance

Maximizing Yield

Ask For a Consultation

Leverage data and analytics for embracing Industry 4.0

Advantages

View how our technology works

Scalable Solutions

Scalable solutions for future for seamless upgrades of features and integration with other IT system/data sources for upstream and downstream linkagesProcess Study

In-depth process study to understand the nuances of specific project scope for your product/serviceSuccess Criteria

As most of the analytics/data science projects have research based probabilistic outcome and is not as deterministic as other IT projects, understanding and setting a process/benchmark for such projects are very importantEngagement Model

Customized engagement model based on requirement and fitmentProduct Agnostic

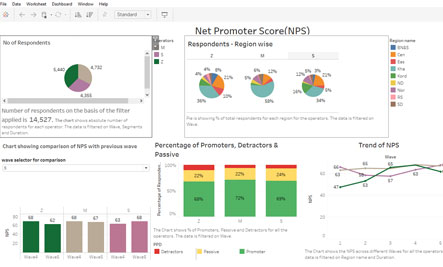

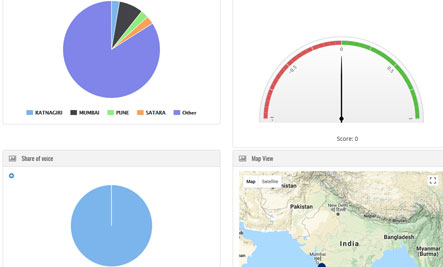

Not limited to ProductsAdaptive Dashboards

Option of both proprietary and open source technology for responsive dashboard for algorithm driven data science applicationsTuned Models

Specific model building & validation for processes as per need starting from machine learning to neural network. No retrofit of pre-build models.

Recommended For You

Our Engagements

Our Engagements